Five Wholly-owned Manufacturing Facilities

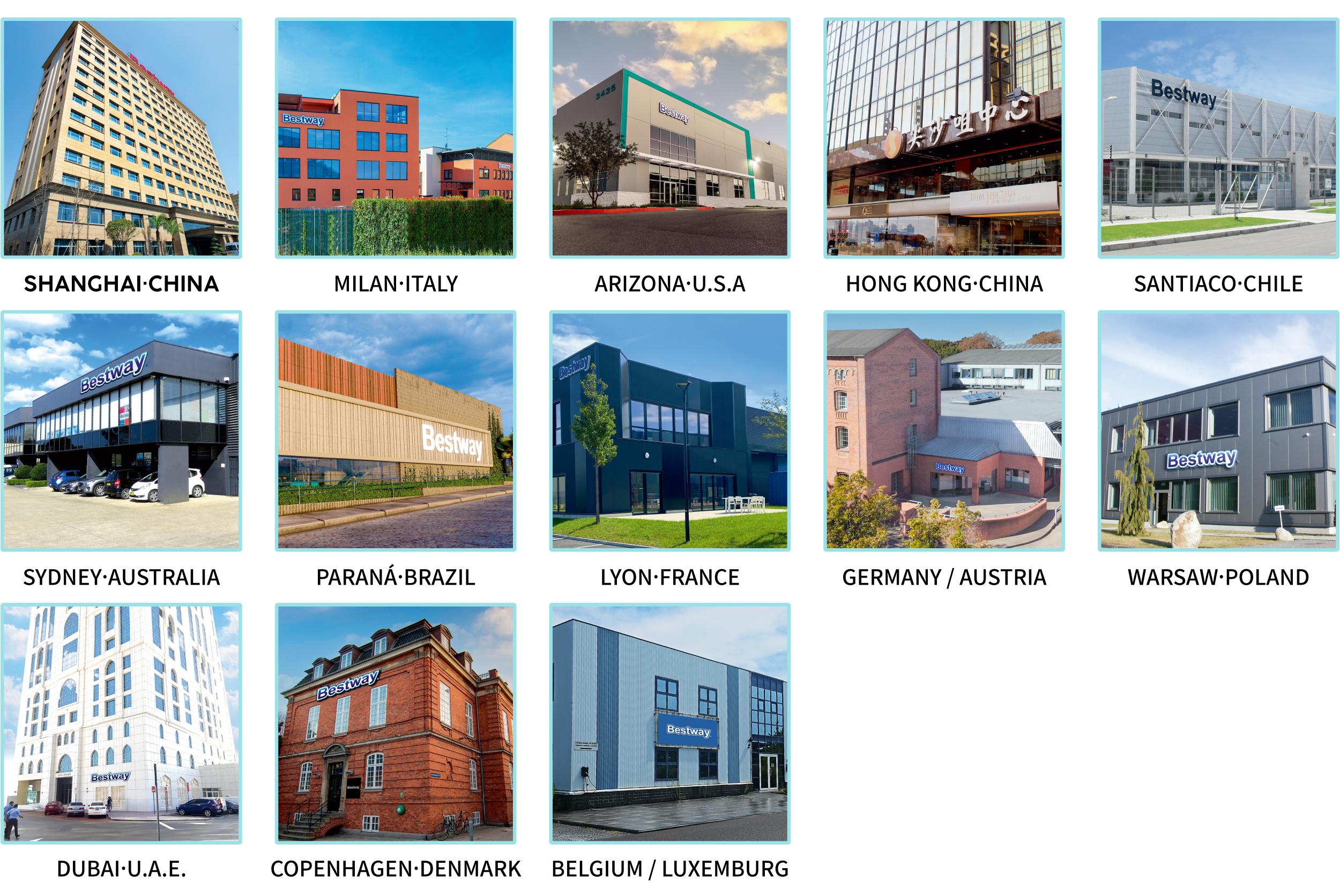

Overseas Subsidiaries

About Us

Bestway Global Holding Inc. is a multinational corporation founded in 1994 in Shanghai, China.

Bestway is the world leader in the inflatable leisure and sports products industries, maintaining one-third of the global market share in these segments.

The "Bestway" brand under Bestway Global is a world-renowned leisure and sports product brand.

Bestway has 13 subsidiaries on five continents, and has established Bestway-brand sales organizations in 82 countries.

Bestway products are sold in more than 120 countries around the world.

Bestway established 3 regional R&D departments located in Europe, the United States, and Shanghai, China.

Bestway also has after-sales service centers in 73 countries around the world.

Bestway wholly owns 5 production facilities in the delta of China's Yangtze River and in Southeast Asia. Bestway facilities span 1.8 square kilometers, housing a grand total of 1.8 million square meters of structures.

Mission & Vision

Mission: Happiness first, satisfied customers, happy employees and a world full of joy.

Vision: Happy work, happy life. By providing satisfactory products and services, we create a happy, long-lasting sports and leisure experience for every person on earth.

Environmental, Social, and Governance

Renewable Energy:

230,000 m² of photovoltaic panels, supplying 20% of annual electricity demand; Biomass boiler has replaced coal-fired boiler at the Vietnam facility.

Eco-Design:

Eco-design principles such as lightweight, modularity, recyclability, and resource efficiency are incorporated into product R&D. Through material and internal structure optimization, the carbon footprint of selected products reduced by approximately 5%.

Circular Economy:

Material Recycling: over 30,000 t of PVC scraps are recycled and reused annually, with products complying with GRS standards.

Sustainable Packaging: 97% of packaging materials are recyclable; Paper packaging contains 90% recycled content, compliant with FSC standards.

Sustainable Packaging: 97% of packaging materials are recyclable; Paper packaging contains 90% recycled content, compliant with FSC standards.

Smart Manufacturing:

$10 million investment in equipment upgrades, supporting improvements in operational efficiency and product quality while saving labor costs.

Low-Carbon Logistics:

Multimodal transport & new energy vehicles introduction, reducing 4,000 t of CO₂ emissions annually.

LIVE IT UP!

Mission: Happiness first, satisfied customers, happy employees and a world full of joy.

Vision: Happy work, happy life. By providing satisfactory products and services, we create a happy, long-lasting sports and leisure experience for every person on earth.

Approximately 1 in 50 people around the world own a Bestway product!

Our Commitment to a Better Future

As a leader in innovations, Bestway is striving to B the Change in the industry. We manufacture our products in 1,820,000 square feet of factory buildings, each covered in solar panels to equal about 50 soccer fields. As an annual recipient of the “Top Performing Supplier on Climate Action” award, we continue to drive sustainable practices forward through four main categories: energy consumption, solar power generation, recycling waste, packaging.

ENERGY CONSUMPTION

Every year,the energy reduction projects prevented 65,000 tons of CO2 emissions over the life of the projects.

SOLAR POWER GENERATION

We are harnessing the power of the sun to operate around 20% solar energy, with plans to expand this going forward..

RECYCLING WASTE

We proudly have ZERO waste to landfill in our operations, with 99.7% of materials recycled in-house or by third parties and 0.3% incinerated. Annually, we recycle an average of 30,000 tons of post-production plastic waste within our own facilities in an effort to Keep Plastic in Play.

PACKAGING

Our boxes are crafted using 90% post-consumer recycled material. Additionally, 97% of our packaging is designed to be recyclable. Our expert teams are working hard to find new and innovative packaging techniques.

Vertically

Integrated

After more than 30 years of development, we've established a vertically integrated way of doing business. Worldwide, we own many facilities dedicated to product development, marketing, logistics and manufacturing.

Our 5 wholly-owned facilities in China and Vietnam cover a total land area of 1.8 million square meters, with facilities of over 1.8 million square meters dedicated to manufacturing plants, logistics centers, warehouses and testing labs.

We believe that keeping the entire process in-house enables us to continually enhance our production, technological and management capabilities to achieve greater production efficiency, reduce waste, and minimize costs while strictly controlling product quality across the value chain. This also ensures punctual product delivery, which in turn translates into happy customers and end-consumers, leading to repeat business opportunities and the strengthening of our brand. Our in-house manufacturing facilities are complemented by well-developed back-end infrastructure. In addition, our major suppliers of raw materials are among the top suppliers globally.

Our Heritage

Company Milestones

Logout

Logout

Login

Login

Create New Account

Create New Account